Established in October 2020, Chiheal Pharma Factory was located in the picturesque "Peony Capital" of Shandong, Heze. This state-of-the-art manufacturing facility is a modern and high-end formulation production base developed and constructed by Chiheal Biomed. It stood as a key investment project for Heze City's Lu Xi New District in 2020 and was incorporated into the significant project directory of Shandong Province by the Shandong Provincial Government in January 2023.

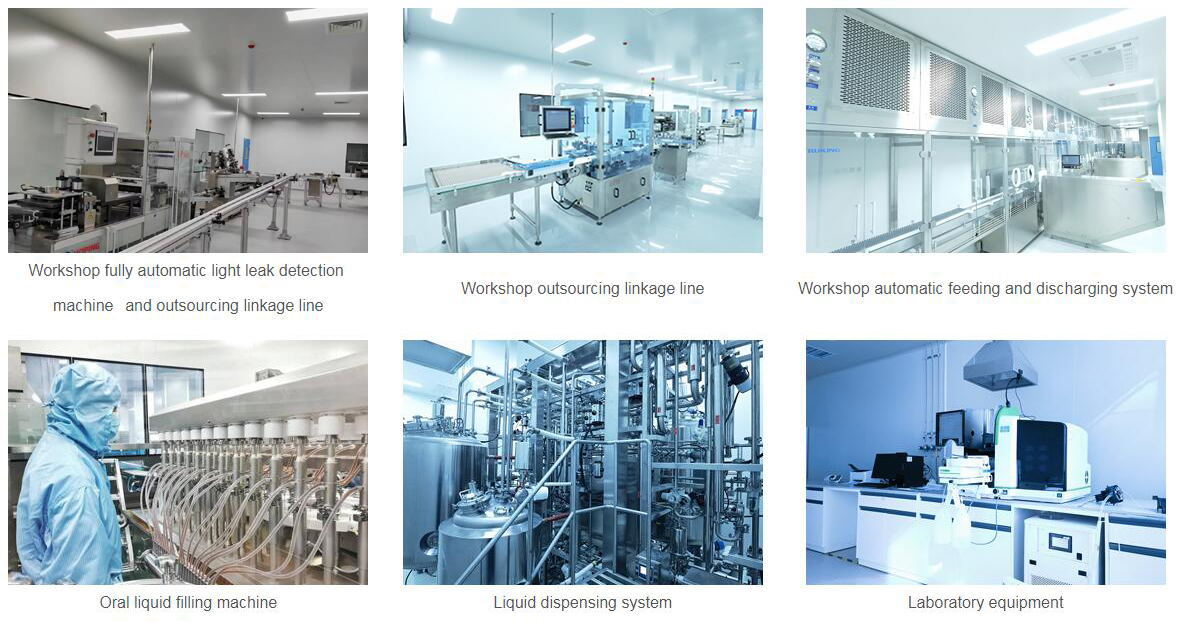

Fully Automated Leak Detection and External Packaging Linked Production Line, External Packaging Linking Line, Automatic In/Out Material System, Oral Liquid Filling Production Line, Liquid Preparation System, Laboratory Testing Instruments, Laboratory Corridor, Instrument Analysis Testing Center, Water Purification System.

Quality Management (QA) – Includes deviation management, change management, quality risk management, complaint management, recall management, annual review management, self-inspection, contract manufacturing and contract testing, data integrity, and computer system management.

Quality Control (QC) – Includes laboratory management, sampling management, reagent and solution management, OOS/OOT management, stability management, titrant management, reference standards and retained sample management.

Validation Management – Includes confirmation and validation management, validation master plan management, user requirements specification (URS) management, equipment qualification, inspection equipment qualification management, computer system validation management, cleaning validation, and process validation management.

Pharmacovigilance – Includes adverse drug reaction (ADR) reporting and monitoring management, drug safety issue handling, ADR analysis and evaluation management, individual case ADR management, PSUR (Periodic Safety Update Report) management, literature retrieval management, etc.

Equipment Management – Includes preventive maintenance management, metrology management, plant implementation management, equipment identification management, pest control management, etc.

Production Management – Includes process protocols, production planning management, product batch segregation management, gowning management, production material requisition management, production hygiene management, clean area management, material balance management, etc.

Material Management – Includes material coding management, material receiving, storage, and issuance management, material inventory management, warehouse area management, etc.

Other Management – Includes human resources management (HR), sales management (SA), environmental, health, and safety management (EHS), procurement management (SM), etc.

Integrated Freeze-Drying/Ampoule Production Line

Specifications: 1 to 50 ml

Annual Production Capacity: 70 million units

Integrated BFS Water Needle/Inhalant Production Line

Specifications: 1 to 20 ml

Annual Production Capacity: 50 million units

Integrated BFS Eye Drop Production Line

Specifications: 0.35 ml

Annual Production Capacity: 70 million units

Hormonal BFS Inhalant Production Line

Specifications: 15 ml

Annual Production Capacity: 30 million units

Anti-tumor Liposome Production Line (Active Drug Loading)

Specifications: 1 to 10 ml

Annual Production Capacity: 15 million units

Anti-tumor Liposome Production Line (Passive Drug Loading)

Specifications: 0 to 50 ml

Annual Production Capacity: 5 million units

Anti-tumor BFS Ampoule Production Line

Specifications: 1 to 20 ml

Annual Production Capacity: 30 million units

Integrated Pre-filled Syringe Production Line

Specifications: 1 ml

Annual Production Capacity: 30 million units

Integrated Oral Liquid Production Line

Specifications: 10 ml

Annual Production Capacity: 100 million units

Integrated Large Capacity Syrup Production Line

Specifications: 50 to 300 ml

Annual Production Capacity: 20 million bottles